Last time I gave y’all a thorough

review of

6 different kintsugi methods

you can choose from based on the needs of your pot-mending situation. After completing this review, out of respect for my current situation as a

graduate student with limited time and funds, I opted to try one of the

simplest methods - the

"2-in-1 Step Method: Oozing Colored Epoxy". As I previously described, this method requires the least supplies,

hands-on steps, and wait time while providing a durable end product. Because

this method had concerns regarding control of the aesthetic quality, my next question was whether these limitations could be improved upon. Hence, today's article covers several trial pots I repaired with this method to observe

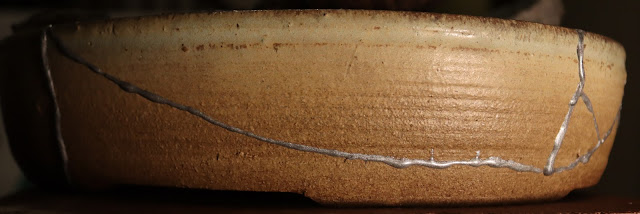

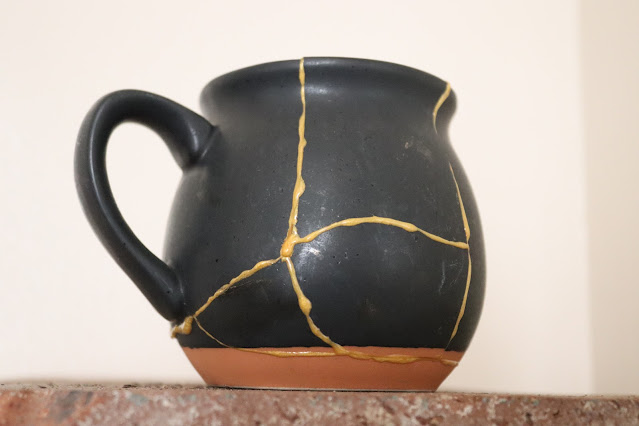

and tweak the 2-in-1 Step technique. My results from the final pot I repaired (see below) advance the 2-in-1

Step Method as it demonstrates the ability to use this method to cleanly

fill large missing pieces in some circumstances, which has not previously

been reported. Combined with the careful application of the colored epoxy, this technique

may now be closer to the quality associated with the more complicated kintsugi repair techniques.

|

The result of my final kintsugi repair using the 2-in-1 Step Method:

Oozing Colored Epoxy.

This piece had a large missing piece and some

small gaps from smaller missing pieces which made it extra challenging

for this technique.

|

Sections

-

Kintsugi Methods (Last time)

-

Traditional Kintsugi Using Natural Products

-

Quick 2 Step: Superglue & Oil Sharpie

-

2-in-1 Step: Oozing Colored Epoxy

-

3 Step: Epoxy Mend, Scrape, & Paint

-

4 Step: Epoxy Mend, Scrape, Lacquer, & Gild

-

Professional 5 Step: Mend, Scrape, Lacquer, & Gild

-

Protocol Summary Table

-

Or... just leave the pot broken!

-

Refining the 2-in-1 Step Method (This time)

-

First Attempt - Silver Show Pot

-

Gold-Repaired Mug

-

Gold Tropical Pot - Blending Unevenness

-

Mini Gold Challenge Pot - Fine Lines, Gaps, and Missing

Pieces.

-

Final Refined Protocol - 2-in-1 Step Method: Oozing Colored

Epoxy

-

Blog Announcements

-

References

IA.2 Traditional Kintsugi Update

Before I dive into the main subject

of this week’s article, let me first note that I have gone back to

my first kintsugi article to expand the section on the

traditional kintsugi method. I previously wrote about the traditional Japanese method involving

natural products for ceramic repair as only a thing of the past, but

surprisingly, an artist living in Italy has proven me wrong. Although the

materials for traditional Japanese Urushi lacquer are hard to come by in

the west, Thom Rozendaal recently experimented with recreating this

natural product with resin from other tree species and a lacquer produced

from insects. My full summary of Thom’s methods, materials, pros, and cons

are available in

my previous article here and you can read more about it directly from

Thom’s art blog here.

Thanks for reaching out, Thom!

|

|

Artist Thom Rozendaal's finished kintsugi repair using only

natural products that were available to him. Read more

here. Source.

|

III. Refining the 2-in-1 Step Method

As I said, I chose to use this

method for my first kintsugi repairs because it is the most efficient

method in terms of time and cost. Here I share several pots I repaired

with this method to see what degree the quality of the final result

could be controlled and to what extent the aesthetic finish

predetermined to random unevenness.

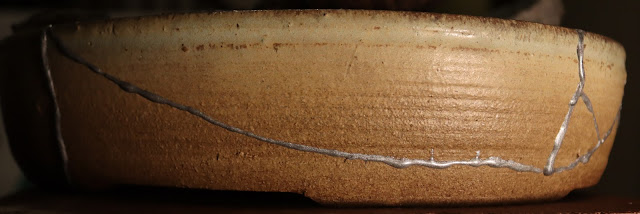

III-I. First Attempt - Silver Show Pot

First, I had a pot that my housemate accidentally knocked down last

winter and needed to be repaired ASAP for my entry into the

2021 Columbus Bonsai Society’s Annual Show

(the first one I’ve participated in with my new club, and likely the

subject of a future blog post). Below are the pictures from this first

attempt. The reason I mended this pot with silver will become apparent

when I share the final tree with y’all in the future. Those who were in

attendance may remember it though. 😉

Since my inner demons include a voice telling me to

procrastinate, my objective with this first pot was to create a solid

and lasting repair using supplies I could find from local art and

hardware stores rather than wait for products to be shipped online. The

supplies I gathered are pictured below. I'll expand on their purposes a

bit here; these basic materials were used for all pots repaired in this

article.

Materials

-

Clear-drying epoxy - To repair the pot and contain our pigment

highlight. Based on my previous article, I would have preferred to

use PC-Clear as it was reported as the most durable. I could not

find it though, so I took a gamble on the Gorilla Glue Clear-Drying

Epoxy.

-

Silver pigment powder - To highlight our crack repair (can substitute

real silver or other metals).

-

Inexpensive brush - I thought I would use this for applying epoxy but

I did not. You don't need it and it would be a waste given you will

need a fresh brush each time the epoxy hardens.

-

Toothpicks - the ideal disposable tool for mixing small volumes of

epoxy, pigment powder, and applying small volumes at a time to the

crack repair.

-

70% Ethanol (or higher) - This was intended to be used with the rag

to remove excess epoxy, but I did not find it very helpful. In some

cases it was used, but the rag is a blunt instrument. I preferred to

smooth out any excess with a toothpick.

- Inexpensive rag - see above

-

Parchment paper (not pictured) - This was the surface I mixed my

epoxy and powder on for easy cleanup.

|

|

Supplies from left to right: Gorilla brand clear epoxy, silver pigment

powder, disposable brush, toothpicks, 70% ethanol, inexpensive rag,

and parchment paper (not pictured).

|

|

|

When life gives you lemons... you intensely review a 400-year-old

Japanese technique and use it to write two excessively long articles

about your lemonade, duhhh.

|

Above you can see how many pieces I had to repair. Luckily

this pot mostly had larger pieces which made the process easier, but it

still took about 1 week to repair the pot in its entirety. Only one or two pieces could be mended at a time, then the pot would have to

be allowed to sit for a day while the epoxy cured.

Below you can see my only shot of the pot repair in

progress. Epoxy was mixed with a toothpick-scoop full of pigment powder

until the desired color was reached. This glue mix was then quickly

applied to the pot as the Gorilla Glue sets in about 5-10 minutes. The

epoxy is easy to apply at first but over time it gets stringy when it gets

close to solidifying. When the epoxy is at this stringy texture, it's a

good time to stop applying and mix a new batch as using epoxy in the

stringy period can become messy and result in epoxy accidentally getting

dragged onto places you didn't intend.

|

|

Here you can see the colored epoxy that has been pushed out of the

crack when these two pieces were first joined. The epoxy appears much

more liquid initially (as in this picture) early on in the setting

process.

|

I wish I had taken more pictures while in the progress of

making the first repaired pot, but alas, my hands were full pressing the

pot back together. With this brand of glue, you should firmly press the

two pieces together for several minutes while the epoxy starts to

harden. More in-progress pictures and pointers will be shared in

subsequent pot repairs detailed later in this article. For now, enjoy

the finished product of this first pot through the pictures below.

|

| Front |

|

| Back |

|

|

Rotated slightly from above.

|

In this first

pot repair, you can see the issues I predicted in the previous article did

manifest somewhat. The lines for this technique certainly can come out uneven

and drips are sometimes apparent due to gravity pulling the oozed epoxy

downwards. For those who are fans of wabi-sabi or the idea of embracing

imperfection, maybe the natural tendencies of this technique are sufficient

for you, and no further adjustments are needed. However, subsequent trials

with this kintsugi technique will see how much this method can be further

refined.

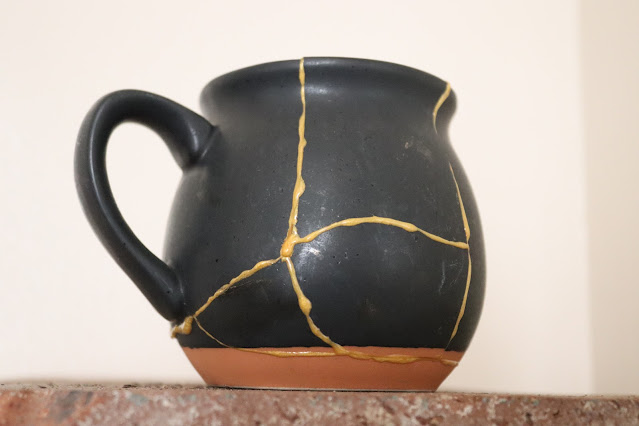

III-II. Gold-Repaired Mug

Next up, a mug that was broken during shipping when I

forgot it in Seattle. Another good chance to practice. This time I tried

using gold pigment powder and took a few more process photos to show the

mixing of the epoxy and how you apply it with the toothpick. I'll let the

pictures and captions tell the story on this one.

*Note: I don't expect this mug will be food-safe after applying the epoxy

because who knows (not me) what the chemicals in the epoxy and pigment

powder would do in the body? This will be a decorative-only piece from now

on.

|

|

Several large broken pieces.

|

|

|

Add the gold powder until the epoxy mix is the color you desire.

|

|

|

Scoop a bit of epoxy mix with the tip of your toothpick. After

scooping, you may want to direct the tip downwards so the drop

accumulates and is easier to apply in a controlled way to your

surface.

|

|

|

On another mug that just had a broken handle, you can see that you

need to apply more epoxy if the area of the break is larger. This

ensures a durable mend.

|

|

|

Front. This mug was another instance of getting used to how the epoxy

behaves. You can see, it is very easy to place too much epoxy on the

crack and get a large and often uneven line.

|

|

| Back. |

III-III. Tropical Pot - Mending and Blending Unevenness

Next up, a tropical pot with two minor

broken pieces around the lip. I don't even remember where this pot came

from or how it broke but I found it in my ceramics collection and

thought "Oh good, another test subject!" This pot is inexpensive,

mass-produced, and the quality is not durable to frosts so under normal

circumstances this is the kind of pot that may not be worth investing a

significant amount of time and money into using more advanced kintsugi

techniques with more expensive ingredients. However, by using the

inexpensive and relatively quick 2-in-1 Step Method on this pot, we can

get more life out of it yet.

|

|

With the flash, this pot takes on a vibrant light blue color.

Under normal lighting though, it is more of a dark blue. I'll show

some pictures both ways throughout. Here you see the two chipped

pieces.

|

|

|

My strategy for this pot was to be more cautious with my

application of epoxy. A little goes a long way, so I first applied

just a light coat and let that set in. You can see that still

resulted in oozing in some areas which dripped together, but in

other areas, the thin layer of epoxy left gaps.

|

|

|

The same trend of drips and gaps is also seen on the inside. Also

on the rim where the crack was very thin, no epoxy was visible on

the outside there even though a solid mend formed.

|

|

|

The previously described uneven areas, gaps, and areas where the

epoxy was not visible despite the crack were fixed by applying a

second coat of epoxy. A thin line was applied on the cracks on the

rim where the epoxy should have been visible and a thicker amount

was applied to gaps and areas where uneven drips had to be blended

together to form a smoother line. Thou can also see a new line

going downwards which covers a crack I noticed after the

fact.

|

|

|

Mended and blended interior.

|

|

|

Finished front view.

|

|

|

Finished corner view.

|

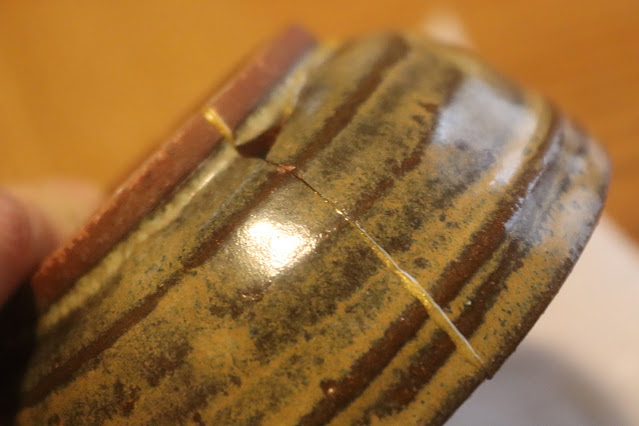

III-IV. Mini Challenge Pot - Fine Lines, Gaps, and Missing

Pieces

Lastly, we have my mini

pot. This pot originated from my former housemate in Seattle. Joey was getting back

into making ceramics so I paid him to make a couple of kusamono-sized

pots. Unfortunately, this one shattered when it was shipped to me after

my move. A year and some change later, time to fix it. As I went along,

I realized that this pot was so thoroughly broken that some areas had tiny pieces to

place back together, some areas had large missing pieces, and other

areas had large gaps where the crack was somehow widened. In total,

these factors made repairing this tiny pot take 2 weeks of on and off

work, but it taught me more than all the other pots combined as the

challenges of this tiny pot required me to try new strategies to get a

consistent-looking product. I would glue a bit one day, let it rest.

Blend some lines one day, let it rest. In some areas, I even scraped

excess epoxy off with a knife in the hours after the epoxy set (while

the epoxy was soft, yet solid), or scraped off finer inconsistencies

after some areas had fully hardened. The work was worthwhile, but now I

have to think of what tree or accent plant would pair with this pot!

It's too nice not to use it.

|

|

Look at all those pieces! I've roughly arranged them by how they

need to go together, then the ones to the right I had no idea

where they went yet.

|

|

|

I was applying the same strategy as the last pot but using even

less epoxy to try to get fine lines. I would first repair the

pieces together and then go over the cracklines again where

necessary.

|

|

|

3 pieces are now stuck back together.

|

|

|

And a fourth! Again, the area with a less than complete hiding of

the crack will be revised later.

|

|

|

Around here I realized what happens if you're not careful about

the order that you put the pieces back together. Although this

piece would go there, it could not be placed in due to the top

piece blocking its entry.

|

|

| Doesn't fit. |

|

| Doesn't fit. |

|

|

Solution! Sand down the edges so that it can squeeze in. This

slowed me down a bit. Better to avoid it.

|

|

|

Finally fits!

|

|

|

I glued the two halves together simultaneously to save time.

|

|

|

Then when the two halves were put back together and there were no

more pieces, I realized I was missing some pieces. Couldn't find

them anywhere, so we will have to get creative.

|

|

|

Small missing piece and a crack that needs another coat.

|

|

|

More gaps were revealed.

|

|

|

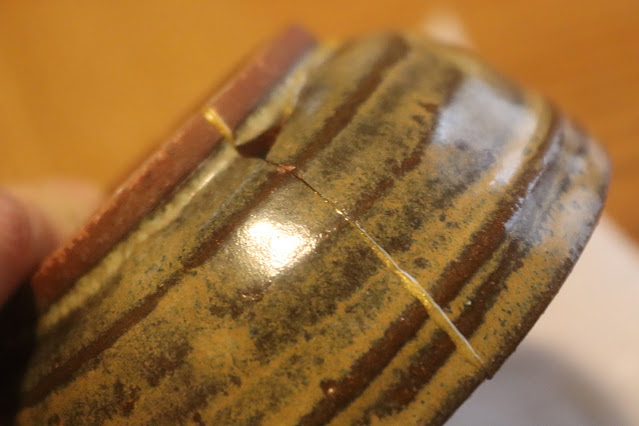

This area had one large missing piece in addition to the large

cracks.

|

|

|

This area turned out pretty well at least. Only minimal blending

is needed.

|

|

|

Here you see the inside view of those gaps, cracks, and missing

pieces. A second coat is needed for many parts.

|

|

|

Inside view of some missing pieces.

|

|

|

My solution to the missing pieces was to cover them with clear

scotch tape on one side. I would then use this to create a smooth

finish on the exterior and drop in the colored epoxy from the

interior.

|

|

|

A few layers of tape to ensure a good surface to apply epoxy on.

|

|

|

Exterior of large missing piece with the tape solution.

|

|

|

Interior of small missing pieces ready to receive the epoxy.

|

|

|

Same solution to the large missing piece from the interior.

|

|

|

For the large missing piece on the rim, I also taped it over the

top to try to ensure the rim of this piece would be relatively

flat with the rest of the pot rim.

|

|

|

Since the inside does not have the tape to create a smooth

surface, the epoxy must be applied with the missing piece resting

down. Gravity will ensure the epoxy I apply spreads evenly and

dries smoothly rather than dripping downwards.

|

|

|

Piece repair is cooking! Since one side was not sealed, I could

feel when the epoxy had hardened and when the tape was therefore

ready to be removed.

|

|

|

After many pieces placed back together and many touch-ups to

perfect and blend the lines, this is the graveyard of toothpicks

from this one tiny pot.

|

|

|

Finished bottom + front.

|

|

|

Finished bottom + back.

|

|

|

Finished inside.

|

|

|

Finished front.

|

III-V. Final Refined Protocol - 2-in-1 Step Method: Oozing Colored

Epoxy

This article is now quite long so I'll only briefly go

over the final protocol with the lessons from the above trials.

Updated Methods:

-

Mix epoxy with pigment powder of choice to reach the desired color.

-

Pick up a drop of epoxy mix with the toothpick, and spread over the

crack such that only a small amount is present on the crack.

-

Using a small amount will enable greater consistency of the line

appearance.

-

Allow pieces to be set fully before building further. Be careful of

the order in which you add pieces so entry of the next piece is not

obstructed.

- If a piece is blocked from entry, sand edges until it fits.

-

If a piece is missing, build a scaffold by applying clear scotch

tape across the gap on the exterior.

-

Arrange the pot so that the taped area rests parallel to the

ground. Gravity will aid in spreading the epoxy evenly on the

interior at the site of the missing piece.

-

Apply the epoxy mix to the inside of the pot until it fills the

void.

-

Apply a very fine (as needed) second coat of colored epoxy over

areas that have gaps, which do not completely hide the crack lines,

or around regions with uneven drops of epoxy from the first

application.

- Scrape excess epoxy off.

-

If a large excess of epoxy is applied in an undesirable location,

it can be easily removed in the first hours while it is still

malleable (before fully drying) with a metal implement.

-

If the epoxy is applied while too tacky, small strings of colored

epoxy may come off with the toothpick after application. These

sloppy strings can land off the line of the crack repair. For pots

with smooth glazes, these small strings can be carefully scraped

off after drying with an Exacto knife, paring knife, or butter

knife.

Materials:

- Clear epoxy

-

PC Clear is preferred for durability, but as discussed last week,

Alardite is slower to set and JB ClearWeld or Gorilla Glue Clear

(among others) may also work.

- Gold/silver powder / mica powder / pigment powder

- Parchment Paper

- Toothpick

- butter knife/paring knife/ Exacto knife

- Scotch Tape

IV. Blog Announcements

-

Now is a perfect time to start preparing to cold-stratify

seeds for them to germinate in spring, so check out my new seed stock for 2022! As always,

all sales come with my 10-Year Bonsai From Seed Guide. These

could be a perfect stocking stuffer for your plant-curious

friends or family members. See my Sales Page for more details on my offerings.

-

Check out my Before & After Portfolio! I've added some new gifs of work that I had done during my

apprenticeship at Elandan Gardens, on my trees, and for past

clients.

-

The Columbus Bonsai Society has a new website! If you're in the area, join us at our next meeting on

January 16th where we will go over what to do if you receive

your first bonsai for Christmas as well as tool maintenance

and sharpening.

More info here.

Thank you! Solved a multitude of problems.

ReplyDeleteHappy to help!

DeleteThank you so much for this. Yesterday I made my first kintsugi attempt, to repair a broken mug that was cracked. I had to break it and reassemble it. I had bought a kintsugi kit from Amazon and it came with no instructions. I made the mistake of trying to glue all the pieces together at once, and of course it kept falling apart (and giving me a small cut in the process!) and the result was a total mess, with gold epoxy all over the mug. I thought all was lost, but today I returned to it and spent some time scraping the mess off with a small metal implement which has worked well. The repaired joins are very thin and not too noticeable. Having read your article, I now know that I can go over it again with a toothpick this time, and I should get a better result. The inside isn't too bad but the lines are rather thick - I'm not too worried about that because they won't be too visible, and I am not going to be using the mug for drinking out of from now on. I think the result is going to be OK in the end, thanks to your fantastic detailed instructions! Thank you!

ReplyDeleteGlad it was useful to you and you could do it!

Delete